The solution was more cooling. It was warping due to too much heat, I increased cooling to 100% and reduced overhang speed slightly and it now prints well.

The solution was more cooling. It was warping due to too much heat, I increased cooling to 100% and reduced overhang speed slightly and it now prints well.

Both ASA and ABS are approved materials. ASA has higher heat defection than ABS, should be easier to print and it smells significantly less when printing.

Fans are completely disabled, except for overhangs and bridges. If I disable fans for overhangs and bridges, they sag like crazy.

I doubt draft shield is going to do anything, the printer is already completely enclosed in a tent. I have around 50-55°C inside the tent.

Edit: I tried a re-print with less cooling for overhangs, it seems to exacerbate the issue significantly.

You’re just making it worse better.

These watches typically come with charging cables, not a docking style station that you put them in. And keeping devices at a perpetual full charge for expended periods of time is a surefire way to kill the capacity quickly.

I mean, I get a full week from my coros pace 2, with 5-6h of GPS cardio tracking (running) and 24h metrics (steps, stress, sleep, etc.) on a 310mAh battery. It takes a whopping 2h to recharge back to full, I would hate having to manage a tiny extra battery to save those 2h of not wearing my watch.

If all you want from a watch is time and alarms, you’re obviously not even remotely in the demographic that any smartwatch is targeting.

The comment I originally commented on compared them as if they were similar tool, (before it was edited), which I simply pointed out it is not. It’s like saying a plane and a helicopter are the same, sure they both are able to lift off the ground, but the similarities kind of stop there.

But they don’t really have similar scopes… One is for technical models, based on extruded 2D drawings, the other is for abstract 3D modelling. Sure in both if them the end product is a 3D model, but they’re achieved in vastly different ways with completely different skillsets and different use cases.

Blender is not CAD software though, it’s 3D modelling software. They’re not quite the same thing, and they’re intended for (and excel at) different things.

Would this be a good entry level device?

Kind of impossible to say right now, it’s not released yet. On paper it seems like a good deal, almost too good at that price point. I wouldn’t buy one until I’ve seen some reviews.

Damn, that’s a crazy low price for a coreXY with a 42.000cm^3 build volume

max resolution of 720p in web browsers

What the fucking fuck!? That shit should be illegal AF if you pay for the 1080p or 4k tier…

I just wish the autocorrect would work…at the moment there is zero difference when I change how aggressive it is in the settings, and it barely makes any suggestions or corrections to typos.

I’m not sure how high the resolution is on resin printers, but the tip of a record stylus is maximum 0.001mm in diameter, here are the specs for records, it’s some pretty small grooves with very fine detail you need for something that’s passable.

That image is not mine, it’s just for reference by the other user to show me where to look

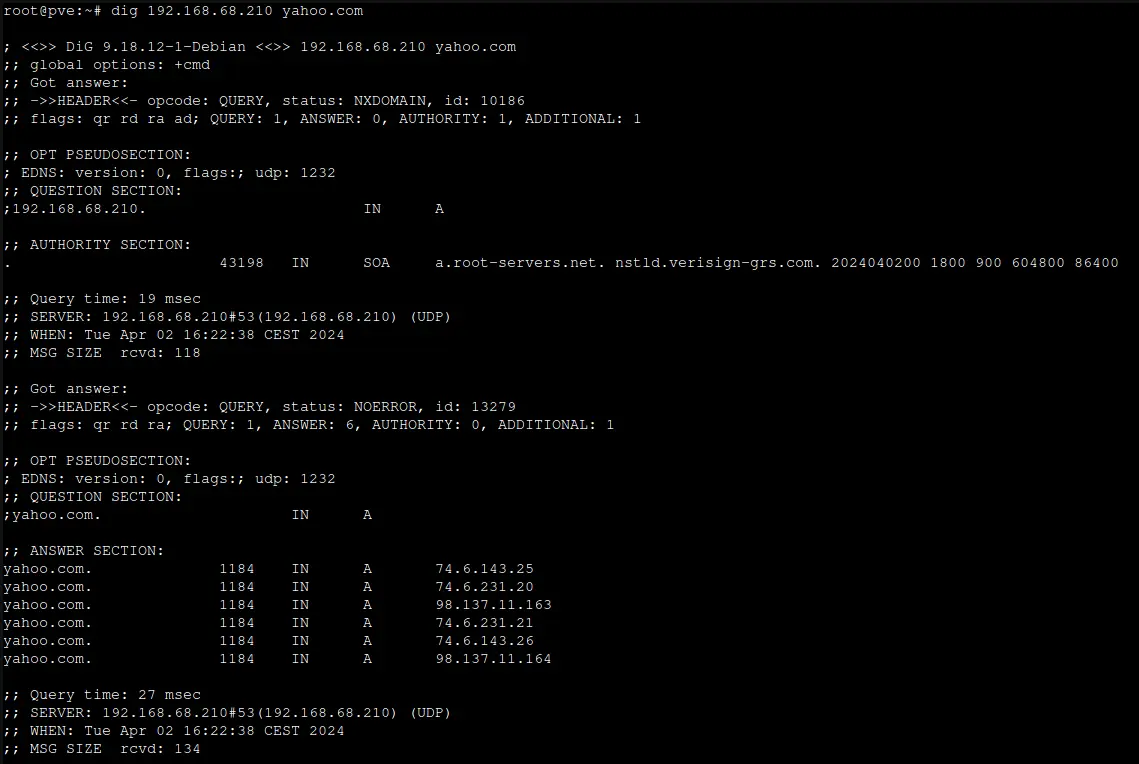

Nothing, and it just reports 100% packet loss when I terminate the ping command.

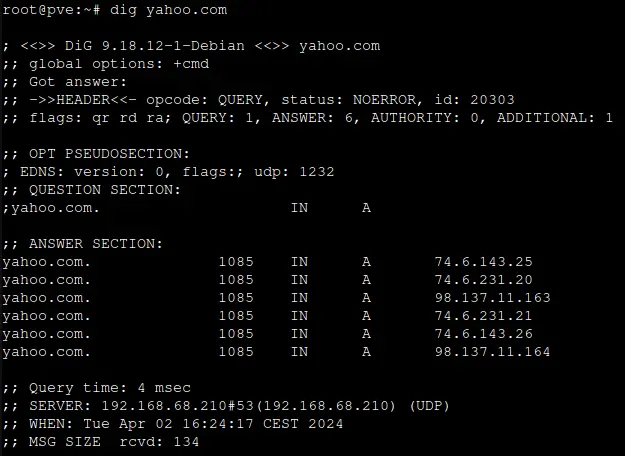

as far as i can tell from the output, i think my DNS is working?

Wow yeah that first one is pretty terrible looking 😅

I’m decently pleased with mine though, but I’m really looking forward to the quality on the voron. I actually already have “the filter” on my current printer (slightly oddly placed in the tent, but it works), and I just connected it directly to the printer PSU and manually turn it on/off with a toggle switch.